In the packaging industry, plastic woven valve bags are widely used in cement, chemical, grain and other fields due to their durability, high load-bearing capacity and environmental protection characteristics.

Product name :

Valve bag making machine for PE/PP/Paper-plastic composite bagItem No :

GC-850-6SOrder(MOQ) :

1Payment :

30% advance payment, 70% balance before shipment or negotiableProduct Origin :

xiamen,chinaShipping Port :

XIAMEN or Or according to your needsLead Time :

3 monthsValve bag making machine for PE/PP/Paper-plastic composite bag

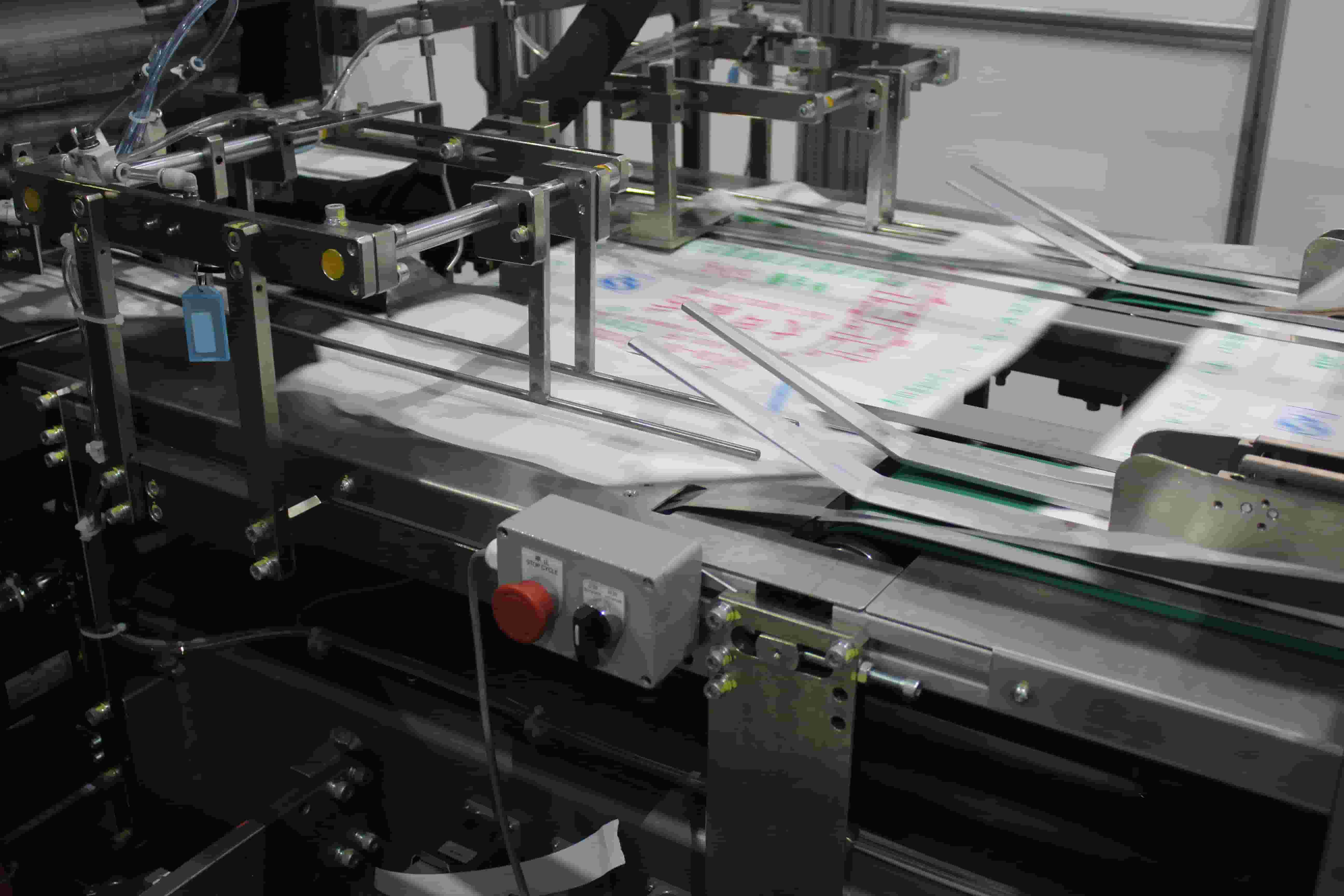

In the packaging industry, plastic woven valve bags are widely used in cement, chemical, grain and other fields due to their durability, high load-bearing capacity and environmental protection characteristics. FK008-Ⅲ fully automatic plastic woven valve bag bag making machine has become the preferred equipment for efficient bag making with its independently developed patented technology, international first-line configuration and intelligent production process. Whether it is a single-layer coated square bottom bag or high-precision printing requirements, this automatic pp woven bag making machine can output stably at a speed of 110-130 per minute, helping enterprises to reduce costs and increase efficiency.

Core advantages

1. Patented technology, efficient and stable

Triangular bag opening technology: independently developed patented design, fast bag opening speed, stable opening, 20% increase in molding efficiency, and reduced downtime maintenance frequency.

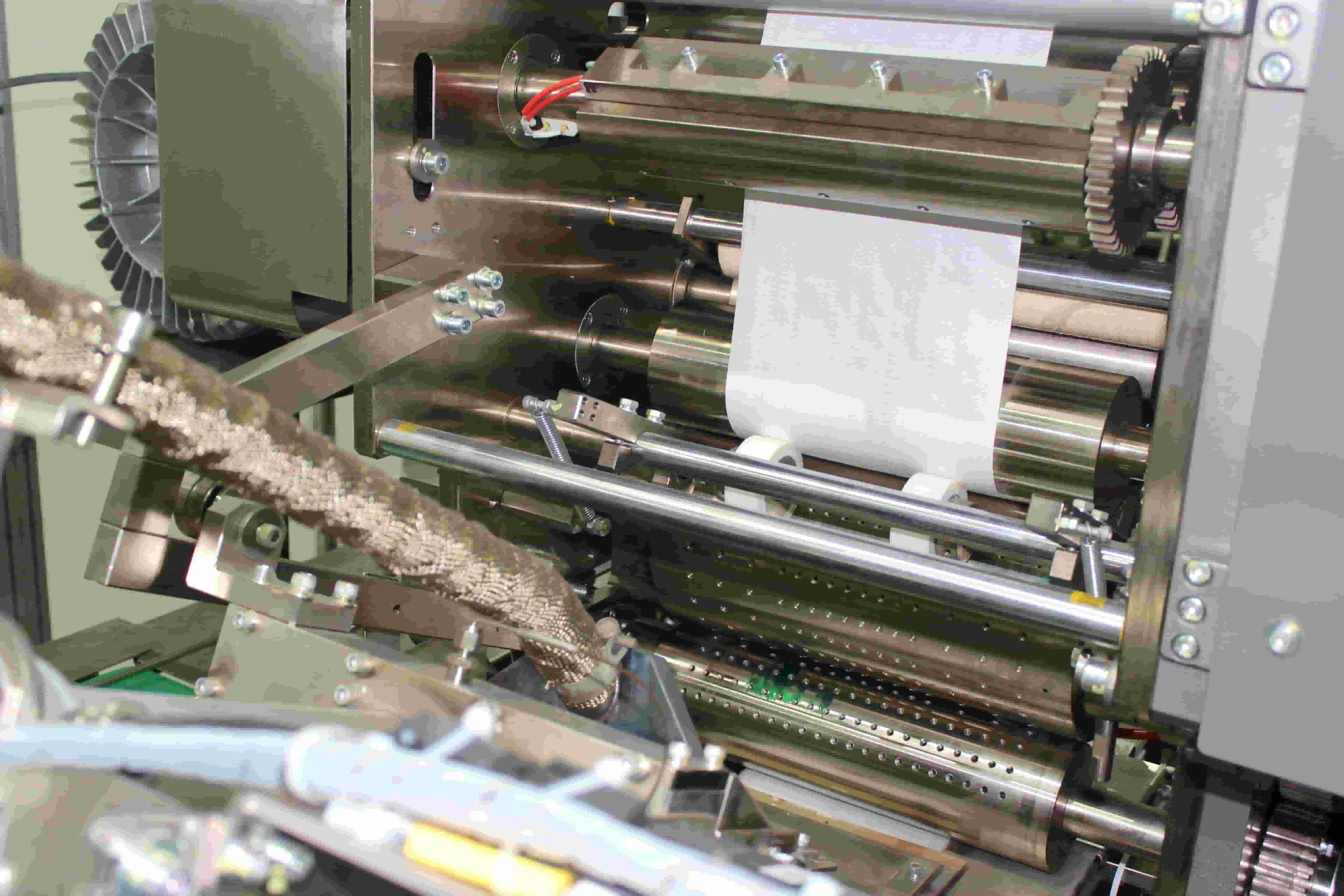

Full servo drive system: precise control of the bag making process, automatic tension adjustment, to ensure that the bag body is flat and wrinkle-free.

Intelligent deviation correction system: using German BST/FIFE deviation correction device, error ≤±3mm, stable coil conveying, and reduced scrap rate.

2. International configuration, quality assurance

Electrical system: Schneider PLC, Panasonic/Omron sensor, Taiwan Weilun touch screen, simple operation interface, support real-time monitoring and parameter adjustment.

Mechanical parts: Japan SHIMPO servo reducer, Germany KTR coupling, SMC/FESTO pneumatic components, to ensure long-term stable operation of the equipment.

Bearings and transmission: NSK/NTN bearings, American Gates timing belts, wear-resistant and pressure-resistant, extend equipment life.

3. Cost saving, green production

Single-side laminating technology: reduce the overlap width, combined with high-precision coating process, every 500 bags produced can save 1 US dollar of raw materials.

Low energy consumption design: installed capacity 150KW, compressed air consumption is only 3m³/min, cooling water is recycled to reduce comprehensive energy consumption.

4. Flexible adaptation, widely applicable

Strong material compatibility: supports PP/PE base fabric (50-80g/m²), lamination weight 18-30g/m², and is suitable for 25-50kg cement bags, chemical bags and other specifications.

Quick changeover: circular knife slitting device and manual adjustment function, parameter switching can be completed within 30 seconds to meet small batch customization needs.

Technical Parameters at a Glance

| Project | Parameters |

| Production speed | 110-130 pieces/minute |

| Bag capacity | 25kg-50kg (cement/chemical materials) |

| Bag weight accuracy | 75g±2g |

| Laminating weight | 18-30g/m² |

| Base fabric width | 1000-1500mm (adjustable) |

| Installation capacity | 150KW |

| Equipment size | 11m (length) × 7.5m (width) × 2.5m (height) |

| Complete machine weight | 16 tons |

Core Configuration and Process

Fully Automated Production Process

Feeding → Tension Control → Punching → Welding → Bag Cutting → Stacking: The whole process is seamlessly connected, supporting one-button start and stop.

Hydraulic Shaftless Feeding Device: Maximum Roll Diameter 1500mm, Load-bearing 1200kg, Suitable for Super Large Mother Rolls.

1. Precision coating and printing

Coating uniformity: peel strength ≥3N/30mm (national standard GB/T8947-1998), edge waste ≤5mm, reducing waste.

High-precision printing: color mark positioning deviation ≤20mm, support multi-color printing, meet brand logo requirements.

2. Intelligent control system

Human-machine interaction interface: Weilun touch screen displays production data in real time, automatic fault alarm, easy to operate.

Three years of free upgrade: The electronic control system is continuously optimized and compatible with future process requirements.

Applicable scenarios

Cement and building materials industry: 25-50kg heavy-duty cement bags and gypsum bags.

Chemicals and minerals: moisture-proof and leak-proof chemical raw material packaging bags.

Food and agriculture: grain storage bags, seed packaging bags.

Why choose FK008-Ⅲ?

High-efficiency production capacity: 130 pieces/minute high-speed production, annual production capacity increased by more than 30%.

Ultra-low loss: raw material utilization rate is as high as 98%, and scrap rate is less than 0.5%.

Worry-free after-sales service: professional team on-site installation and training, three-year free electronic control upgrade, and lifelong technical support.

FK008-Ⅲ fully automatic valve bag bag making machine takes innovative technology, international quality and intelligence as the core, providing enterprises with a one-stop solution from raw materials to bags. Whether it is large-scale production or customized needs, this automatic block bottom valve bag making machine can help you seize the market opportunity with excellent performance and reliability. Consult now to start a new era of efficient bag making!